Product Description

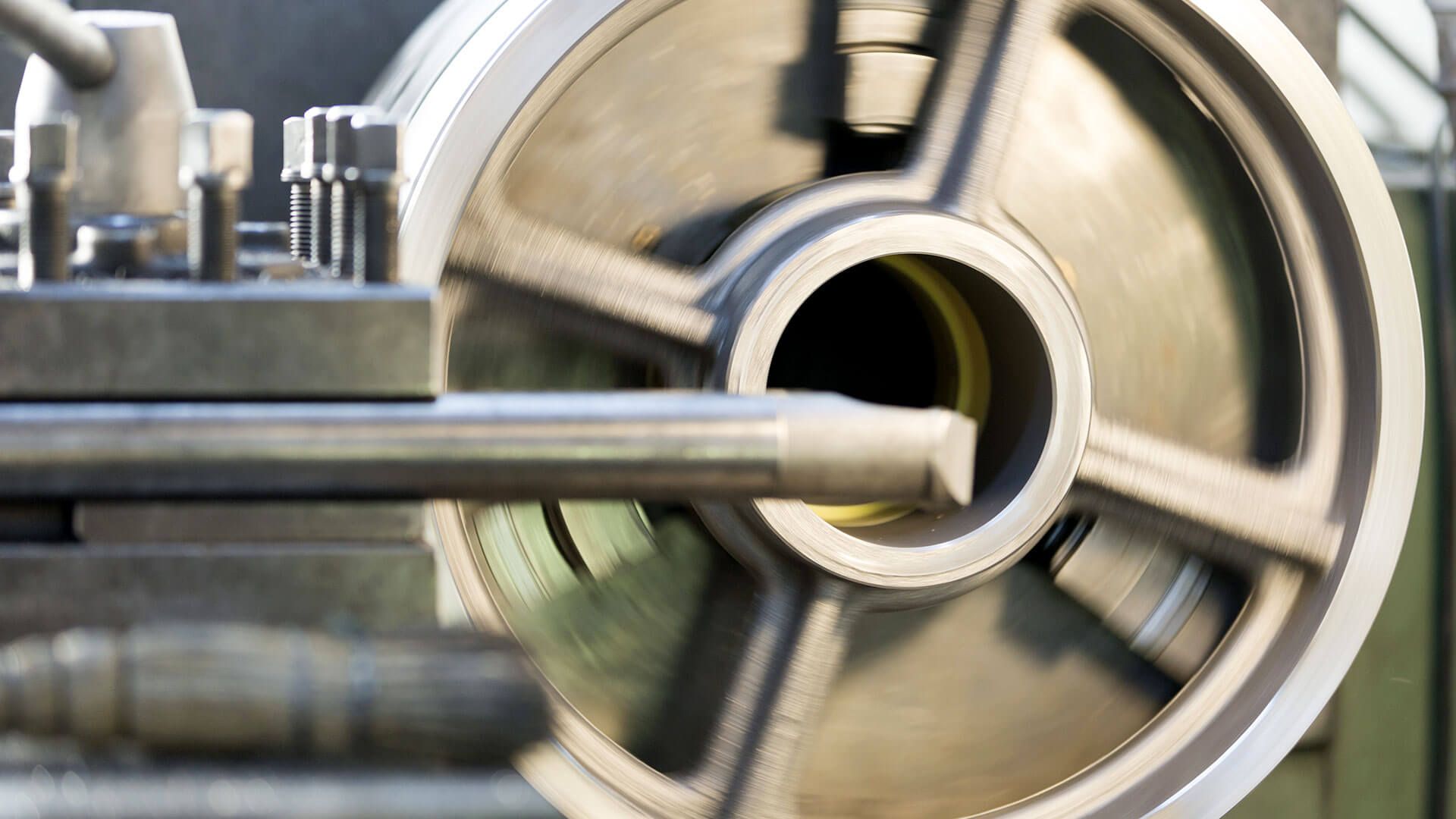

Pulley Lagging Pad

Lagging Pad is widely used in different kinds of bucket elevator for head pulley, large-scale coal mine colliery, steel mill, cement plant cement mill, and other port conveyor machine.

- Wear-resisting rubber with Pattern: use high elasticity, high wear-resisting rubber raw material, adopt the special rhombus groove and Z groove structure, increased coefficient of roller surface, higher accessory traction make the roller lifespan longer;

- Cohesion: use the high-pressured vulcanization technology make the steel plate and rubber plate cohere, make these 2 material stable, and prevent it from degumming.

- Steel linear plate: precision shaping to arc in the factory, suitable for different diameter of rollers, make steel linear plate and roller circular arc camber plying-up completely, make steel linear plate long-running stability.

- Steel retainer: it is burnt or fixed on head pulley or roller arc by screw, make lagging pad rigid fixation and install correctly, lagging pad would not displace or pull-out, avoid shock loading, then the belt would not result lagging pad displace when the material blocked.

| Rubber Compound | |

| Polymer | NR / SBR |

| Tensile Strength | 17.5 N / mm3 |

| Hardness Shore A | 60+/- 5 |

| Elongation at break | 400% |

| Specification | |||

| Type | Standard width. mm | Thickness.mm | Length.mm |

| Level Type | 138 | 15 | 1830 / 2000 |

| Inclined Type | 138 | Side 15, middle 18 | |

Note:

* Length can be cut according to actual pulley width

* Drum diameter and width is very important to order.

* The radian of lagging pads will be prefabricated well according to drum diameter before deliver

Related Products:

Company profile:

HangZhou CHINAMFG Machinery Co., Ltd manufacture and export conveyor parts in China.

Our Business:screw conveyor, chain conveyor, belt conveyor, bucket elevator, Roller mill, Purifier Bin Filter, spout pipe, sieve cleaner, chain ,all kind of machines and components for flour mill ,feed mill, rice mill , and other bulk material handling industry.

Exported country:South Asia, South Africa, West Africa, South American and Russia and the Philippines.

QC standard:All the products are tested before delivery according to relevant International Standard or customers’ requirements.

OEM service: Besides the international standard products, we can also design and manufacture new products according to drawings or requirements.

Our purpose:With more than 20 years experience in the bulk material handling industry, we hope to become one-stop suppliers for all the different machines and components.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | 1 Year |

|---|---|

| Transport Package: | Wooden Box |

| Specification: | width: 135mm |

| Trademark: | AGS |

| Origin: | Zhenjiang |

| Samples: |

US$ 99/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there different types of elevator pulleys, and how do they vary in elevator systems?

Yes, there are different types of elevator pulleys that vary in design and function, depending on the specific requirements of the elevator system. Here’s a detailed explanation of the various types of elevator pulleys:

- Drive Sheave: The drive sheave pulley is an essential component in traction elevator systems. It is connected to the drive machine and is responsible for transferring the torque from the motor to the elevator cables. The drive sheave pulley has grooves that grip the cables, providing the necessary traction for the elevator car to move. The size and design of the drive sheave pulley are customized based on factors such as load capacity, speed, and motor specifications.

- Deflector Sheave: Deflector sheave pulleys are used in traction elevator systems to change the direction of the cables. They guide the cables from the drive sheave to the elevator car and counterweight, ensuring proper alignment and movement. Deflector sheave pulleys are typically smaller in size compared to the drive sheave pulley and are designed to minimize friction and wear on the cables.

- Idler Sheave: Idler sheave pulleys are used in traction elevator systems to provide additional cable support and guidance. They are positioned between the drive sheave and the deflector sheave, distributing the load and maintaining cable tension. Idler sheave pulleys help reduce the bending stress on the cables and ensure smooth cable movement throughout the elevator system.

- Compensation Sheave: Compensation sheave pulleys are used in some elevator systems, particularly those with long travel distances. They are responsible for compensating for the weight of the elevator car and counterweight, ensuring that the tension in the cables remains constant as the elevator moves. Compensation sheave pulleys typically have a larger diameter and are equipped with a spring mechanism to maintain proper cable tension.

The selection and use of different types of elevator pulleys depend on the specific design and requirements of the elevator system. Factors such as load capacity, speed, travel distance, and cable configuration influence the choice of pulleys. By utilizing the appropriate types of pulleys, elevator systems can achieve efficient and reliable operation, ensuring smooth movement, proper cable alignment, and optimized load distribution.

What safety considerations should be kept in mind when designing and installing elevator pulleys?

Designing and installing elevator pulleys require careful attention to safety. Here are some important safety considerations to keep in mind:

1. Load Capacity and Safety Factors: Ensure that the selected pulleys have an adequate load capacity to handle the maximum anticipated load. Consider safety factors to accommodate unexpected loads or dynamic forces that may occur during operation.

2. Material Strength and Durability: Choose pulleys made from high-quality materials that possess the necessary strength and durability to withstand the stresses and forces exerted on them. Proper material selection helps prevent premature wear, fatigue, and failure.

3. Redundant Safety Systems: Incorporate redundant safety systems, such as overspeed governors and safety brakes, into the elevator design. These systems work in conjunction with the pulleys to provide additional layers of protection against uncontrolled descent, excessive speed, or other potential hazards.

4. Proper Alignment and Tension: Ensure that the pulleys are properly aligned and tensioned. Misalignment or inadequate tension can lead to increased friction, premature wear, and reduced performance. It is important to follow manufacturer guidelines and industry best practices for pulley installation and maintenance.

5. Regular Inspections and Maintenance: Implement a comprehensive inspection and maintenance program for the elevator system, including the pulleys. Regular inspections help identify any signs of wear, damage, or malfunctioning components. Timely maintenance and repairs are essential to address any issues and maintain the safety and performance of the pulleys.

6. Compliance with Regulations: Adhere to local, national, and international regulations and safety standards specific to elevator design and installation. These regulations cover various aspects of elevator safety, including pulley requirements, load capacity limits, emergency procedures, and periodic inspections.

7. Qualified Professionals: Engage qualified professionals, such as elevator engineers or consultants, who have expertise in elevator design and safety. Their knowledge and experience can ensure that the pulleys are designed and installed in compliance with safety standards and best practices.

By considering these safety considerations during the design and installation of elevator pulleys, it is possible to minimize risks, enhance the safety of the elevator system, and provide a reliable means of vertical transportation.

In which parts of an elevator system are elevator pulleys typically found?

Elevator pulleys are typically found in the following parts of an elevator system:

1. Machine Room: In most elevator systems, the elevator pulleys are located in the machine room, which is a designated space typically situated at the top of the elevator shaft or adjacent to it. The pulleys are mounted on the drive system and connected to the elevator motor.

2. Top of the Elevator Shaft: Elevator pulleys, specifically the traction sheave in traction elevator systems, are positioned at the top of the elevator shaft. The traction sheave is directly connected to the motor drive system and is responsible for providing the necessary traction for the elevator car to move.

3. Elevator Car: The elevator pulleys are present inside the elevator car itself. They guide and support the elevator cables or ropes that are attached to the top of the car and extend upwards to the pulleys at the top of the shaft. The pulleys inside the car help ensure smooth movement and proper distribution of tension during vertical transportation.

4. Elevator Counterweight System: Elevator systems often incorporate a counterweight system to offset the weight of the elevator car. The counterweight is connected to the opposite end of the elevator cables and moves in the shaft alongside the car. The elevator pulleys guide and support the counterweight cables, ensuring synchronized movement between the car and the counterweight.

These are the primary locations where elevator pulleys are typically found in an elevator system. Their placement and function in these areas are essential for the safe and efficient vertical transportation of passengers or goods.

editor by CX

2024-05-17